Utility Actuation

Whippany Actuation Systems develops custom actuation solutions for complex utility motion control requirements. The technology leader in electromechanical utility actuation, our products save considerable weight over hydraulic systems.

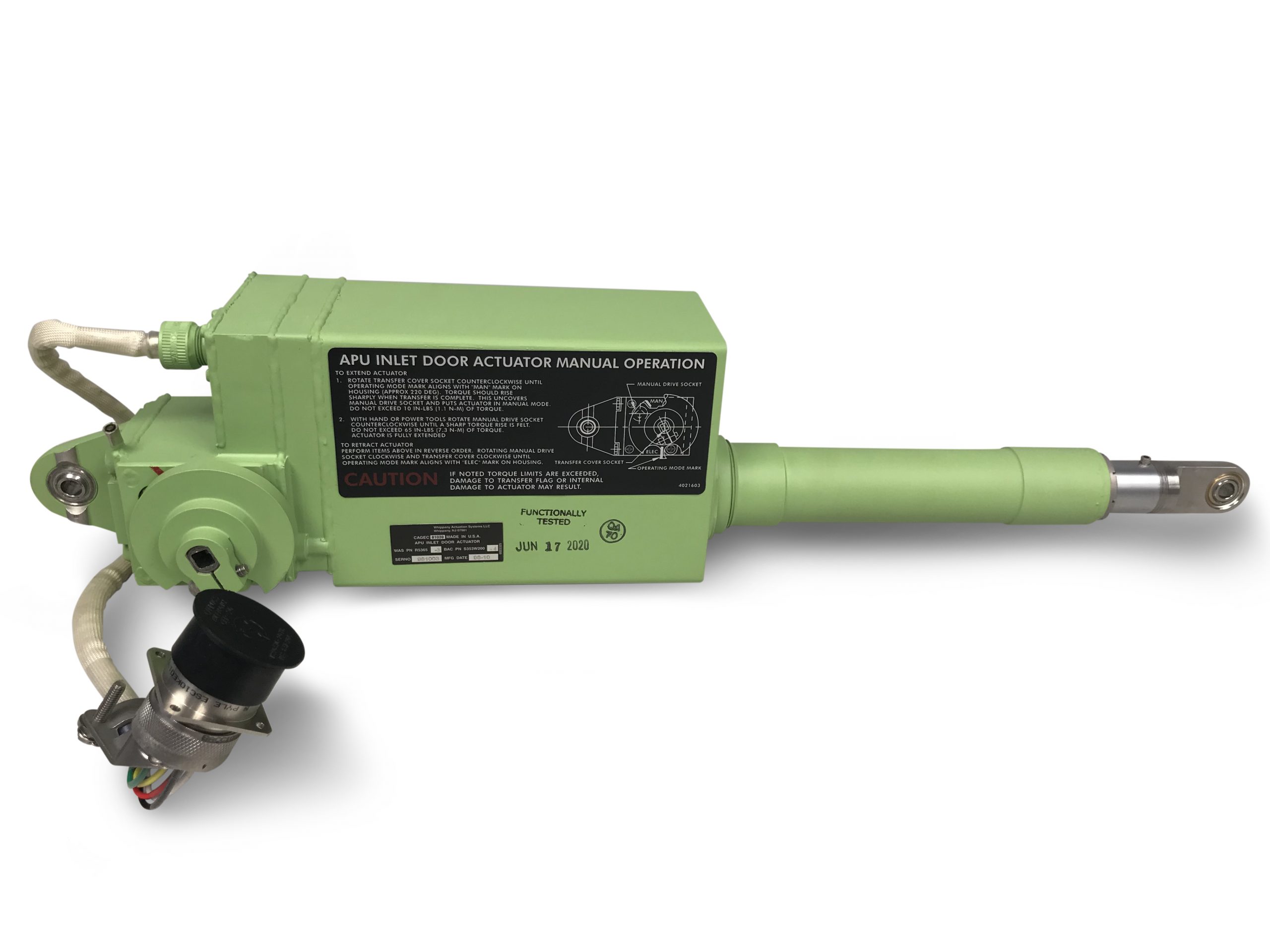

Door Actuation

Our exceptionally reliable door, canopy, and latch actuators are designed for a variety of doors and latches not located on flight critical surfaces.

- APU Door Actuation

- Air Stair Door Actuation

- Cargo Door Actuation

- Baggage Door Actuation

- Canopy Actuation

- 28VDC, 270VDC, +/-270VDC mtors

- Active-Active and Active-Standby Motor Architectures

- Ball Screw and Acme Linear Actuators and Geared Rotary Actuators

- Clutches, Brakes, Dampers, and Skewed Roller Devices

- Custom DC and AC Motors

- Brushless DC and AC Drive Solutions

- Transport

- Cargo

- Helicopter

- eVTOL

- Hypersonic

- UAV

- Products

-

- APU Door Actuation

- Air Stair Door Actuation

- Cargo Door Actuation

- Baggage Door Actuation

- Canopy Actuation

- Features

-

- 28VDC, 270VDC, +/-270VDC mtors

- Active-Active and Active-Standby Motor Architectures

- Ball Screw and Acme Linear Actuators and Geared Rotary Actuators

- Clutches, Brakes, Dampers, and Skewed Roller Devices

- Custom DC and AC Motors

- Brushless DC and AC Drive Solutions

- Applications

-

- Transport

- Cargo

- Helicopter

- eVTOL

- Hypersonic

- UAV

Payload Actuation

For aircraft focused on speed and stealth, keeping weapons internal is essential. Whippany’s payload actuation opens doors and extends weapon systems when necessary. Our payload door actuation solutions support a range of aircraft from large transport category airplanes to UAVs.

- Precision Door Actuation

- Payload Door Uplocks

- Weapon Extension / Retraction

- Aiming and Stabilization

- Fault Tolerant, Redundant Control Architectures

- Digital and Analog Interfaces

- Active-Active and Active-Standby Motor Control

- Fully Digital 3-Loop Control: Position, Velocity, Current

- High-Performance Sinusoidal and Trapezoidal Motor Drives

- 28 to 270VDC+; up to 200 Amps

- Regenerative Energy and Thermal Management

- Moisture Management

- High Shock and Vibration; HIRF Environments

- Custom AC and DC Motor Designs

- High Power Density Rotary and Linear Actuation Solutions

- Transport Aircraft

- Cargo Aircraft

- UAV

- Helicopter

- eVTOL

- Hypersonic

- Products

-

- Precision Door Actuation

- Payload Door Uplocks

- Weapon Extension / Retraction

- Aiming and Stabilization

- Features

-

- Fault Tolerant, Redundant Control Architectures

- Digital and Analog Interfaces

- Active-Active and Active-Standby Motor Control

- Fully Digital 3-Loop Control: Position, Velocity, Current

- High-Performance Sinusoidal and Trapezoidal Motor Drives

- 28 to 270VDC+; up to 200 Amps

- Regenerative Energy and Thermal Management

- Moisture Management

- High Shock and Vibration; HIRF Environments

- Custom AC and DC Motor Designs

- High Power Density Rotary and Linear Actuation Solutions

- Applications

-

- Transport Aircraft

- Cargo Aircraft

- UAV

- Helicopter

- eVTOL

- Hypersonic

Blade & Tail Fold Actuators

Whippany offers a full suite of electric helicopter blade and tail fold actuation systems, allowing militaries to safely and effectively store more rotorcraft in smaller areas, such as aircraft carriers.

- Blade folding

- Index drives

- Pin puller actuators

- Pitch lock actuators

- Fault tolerant, redundant control architectures

- Digital and analog interfaces

- Active-active and active-standby motor control

- Fully digital 3-loop control: position, velocity, current

- High performance sinusoidal and trapezoidal motor drives

- 28 to 270VDC+; up to 200 amps

- Regenerative energy and thermal management

- Moisture management

- High shock and vibration; HIRF environments

- Custom AC and DC motor designs

- High power density rotary and linear actuation solutions

- Helicopter

- Products

-

- Blade folding

- Index drives

- Pin puller actuators

- Pitch lock actuators

- Features

-

- Fault tolerant, redundant control architectures

- Digital and analog interfaces

- Active-active and active-standby motor control

- Fully digital 3-loop control: position, velocity, current

- High performance sinusoidal and trapezoidal motor drives

- 28 to 270VDC+; up to 200 amps

- Regenerative energy and thermal management

- Moisture management

- High shock and vibration; HIRF environments

- Custom AC and DC motor designs

- High power density rotary and linear actuation solutions

- Applications

-

- Helicopter

Environmental Control Actuation

Whippany Actuation Systems features a product line of actuators supporting Environmental Control Systems (ECS) OEM manufacturers.

- Cabin Environmental Control Valve Actuators

- RAM Air Door Actuation

- Mixing Valve Actuation

- Ball screw and acme linear actuators

- Geared rotary actuators

- Permanent magnet brushless DC, DC stepper, and AC synchronous motors

- Absolute position sensors

- Manual drives

- Transport

- Cargo

- eVTOL

- Hypersonic

- Helicopter

- Products

-

- Cabin Environmental Control Valve Actuators

- RAM Air Door Actuation

- Mixing Valve Actuation

- Features

-

- Ball screw and acme linear actuators

- Geared rotary actuators

- Permanent magnet brushless DC, DC stepper, and AC synchronous motors

- Absolute position sensors

- Manual drives

- Applications

-

- Transport

- Cargo

- eVTOL

- Hypersonic

- Helicopter

Case Study

Lightweight Mission Equipment Latch Release

A major aircraft OEM needed to evolve beyond their previous application for mission equipment latch releases—hydraulic rams coupled with valves and tubing. The manufacturer sought a dual redundant electromechanical solution to simplify maintenance and improve reliability.

The customer held high expectations for the project. Our team needed to create a dual electrical redundancy system designed to meet high loads and extreme environments in a small envelope while achieving a probability of loss of function acceptable for mission success.

Whippany Actuation Systems adapted a proven actuator, certified on a commercial aircraft landing gear latch release, by adding interface provisions that were specific to the customer’s requirements. Our team was able to swiftly provide actuators for test purposes to secure the contract. Within 14 weeks of receiving the order, we delivered the new flight-worthy actuators, meeting the critical customer need on schedule.

Lightweight Utility Actuation

Learn more about our off-the-shelf and custom electric actuation solutions reliably designed to save critical weight.